The

Internet of Things is one of the major enablers of SC cohesion. Ben-Daya et al. (2017) defined it as a network of physical

objects that are digitally connected to sense, monitor and interact within a

company and between the company and its supply chain enabling agility,

visibility, tracking and information sharing to facilitate timely planning,

control and coordination of the supply chain processes. Some authors like Tu

(2018) argues for the transparency that IoT brings to SCM due to the global

network of physical objects. Mainly devoted to the SC delivery processes,

transformation or even food SCs, IoT could help manage SC remotely, provide

more precise information and ensure better coordination between different

entities for effective decisions taken.

IoT

improve previous technologies in SC. As showed Tu et al., its outperforms

current barcode-based system regarding labor cost,

efficiency, and operational adaptiveness. Their potential favour exchanges

between SC members. Thus, Haddud et al. (2017)

confirm the significance impact of IoT potential benefits to individual organizations

and their entire supply chains. Its contribute to build critical success

factors for successful SCM. Cui et al. (2022) provide most important measures

of the IoT in improving SC. i.e. improving information transparency,

strengthening the integration of management information systems and improving

large data processing abilities.

Figure 4 : topics

developed in IoT papers

The

nine articles selected on IoT develop different topics: productivity, SC

sustainability and innovation or servitization. But,

by considering that some technologies like RFID or more widely IT in business,

are initial stage of IoT, 27 others papers must be considered. The figure 4

provides details for IoT specific papers.

Analysing

the impact of IoT in retail sector, De Vass et al. (2021) reveal that multiple

IoT forms provide additional capabilities in data auto-capture, visibility,

intelligence, and information sharing for greater integration of retail supply

chains. That, in turn, enhances supply chain performance in cost, quality,

delivery, and flexibility dimensions to improve firm financial, social, and

environmental sustainability. From purchasing side, IoT help to work with

dynamic and complex markets. Its also supports the

development of a more capable and efficient Purchasing and Supply Management

organisation (Legenvre et al., 2021).

Internet

of Things takes supply chain communications to another level: the possibility

of human to things communication and autonomous coordination among ‘things’

while being stored in a facility or being transported between different supply

chain entities (Ben-Daya et al., 2017). This

technology will allow the reduction in the time between data capture and

decision-making that enables supply chains to react to changes in real time

allowing levels of agility and responsiveness never experienced before (Ben-Daya et al., 2017, Ellis et al., 2015). With these

possibilities, IoT provides more capabilities to react when risks arise.

Prim

et al. (2021), present the IoT and Big Data as tools for real-time monitoring

of supply chain processes, supporting proactive decision-making, reducing

operational costs and improving product quality. They also claim that a

collaborative partnership would reduce the learning curve and barriers to

adoption, and increase the likelihood of successful implementation. Blockchain

bring more security to the above collaborative partnership.

Blockchain

is considered as a distributed database of common public/private records or

ledgers of all digital transactions that have been executed and shared between

agents participating in the chain (Benhayoun et Saikouk, 2022 ;Saberi et al.,

2019). Though Blockchain Technology (BT)–SCM integration is still in its

infancy (Queiroz et al., 2020), from Swan (2015) perspective, its enables

timely and more efficient business relationships. It mitigates risks and

reduces transaction costs. It overcomes currency fluctuations and speculation

between shipper and importers as well as other stakeholders. It verifies the

origin of a product by providing information on time, place and manufacturers,

and offers information on its journey from suppliers to consumers (Lesueur-Cazé et al., 2022; Benhayoun

et Saikouk, 2022). Decentralization bringing out by

Blockchains promotes security as it makes less likely to crash, be corrupted or

hacked (Benhayoun and Saikouk,

2022; Tian, 2016). The double spending and double-booking problems can also be

easily solved by the blockchain as there will only be one transaction related

to the previous and ongoing block in the chain that can be approved.

There

are other technologies such as Direct Digital Manufacturing (DDM), Cloud, Big

Data or Cyber-physical systems and they contribute to improve products or

improve their ability to meet customer demand. For example, in food industry,

Ali et al. (2021) noted that the main drivers for the adoption of Industry 4.0

technologies are cost optimization, food safety concern, facilitation of

regulatory compliance and the ability to better match supply and demand.

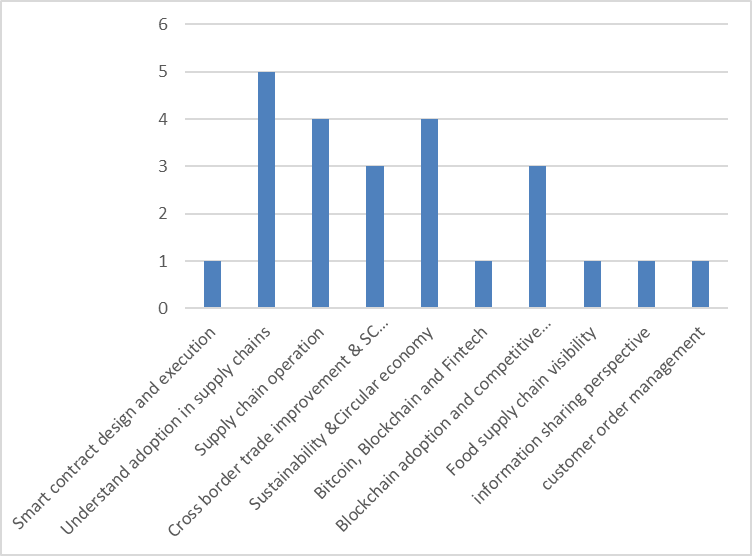

The

above figure 5 present topics addressed by Blockchain technology.

Most

of papers deal with BT adoption, its importance in SC efficiency or SC

sustainability in developed and emerging economies. Economies in which there are differences in

the variables that determine the BTs as well as their stage of diffusion (Wamba

and Queiroz, 2022).

Figure 5 :

topics developed in blockchain papers

Foremost,

while Queiroz et al. (2021) pointed out that, the most critical constructs that

directly affect BT adoption in emerging economy are facilitating conditions,

trust, social influence, and effort expectancy, Kamble

et al. (2019) found that the technology readiness index constructs-Insecurity

and discomfort have an insignificant effect on the perceived ease of use and

usefulness. For these authors, perceived usefulness, attitude, and perceived

behavioural control affect the behavioural intention. They found that,

subjective norm has a negligible impact on behavioural intention. Finally, Wong et al. (2020) revealed that

facilitating condition, technology readiness and technology affinity have a

positive influence on intention to use BT in SC and regulatory support

moderates the effect of Facilitating Condition.

While

most of papers on BT seek to understand its importance in SC, others provide

insight for its implementation within SC operations as well as in SC

sustainability. For Wang et al. (2019), the value of such technologies for

supply chain management lies in four areas: extended visibility and

traceability, supply chain digitalization and disintermediation, improved data

security and smart contracts.

Widely,

blockchain could transform practice, including enhancing product safety and

security, improving quality management, reducing illegal counterfeiting,

improving sustainable supply chain management, advancing inventory management

and replenishment, reducing the need for intermediaries, impacting new product

design and development, and reducing the cost of supply chain transactions

(Cole et al., 2019). The above efforts are more-oriented toward improving

operational-level capabilities (information sharing and coordination

capabilities) than strategic-level capabilities (integration and collaboration

capabilities) within SC (Nandi et al., 2020).

According

to the first group of authors, implementing Blockchain helps to fulfilling SC

goals of performance. Therefore, dealing with inefficiency within SC operations

Xue et al. (2021) find that blockchain is a helpful

tool to realize the goal of SC management to reduce cost, improve quality and

enhance the overall efficiency of the system. Blockchain improves the

efficiency of the process: it reduces the number of operations, reduces the

average time of orders in the system, reduces workload, shows traceability of

orders and improves visibility to various supply chain participants (Rogerson

et Parry, 2020; Martinez et al., 2019, Wang et al., 2019). Blockchain

technology (BT) increases the operational transparency of the Supply Chain and

the trust that is built between members of the Supply Chain, which improves

coordination (Dubey et al., 2020). BT largely contributes to the improvement of

demand forecasting in SCs (Benhayoun et Saikouk, 2022).

For Azzi et al. (2019), the BT is introduced to achieve the

supply chain’s objectives, by reducing the risk emerging from the tracking

system and data management. More, competitive performance is directly improved

through blockchain adoption and also indirectly through blockchain-enabled

process and relational innovation (Fosso Wamba and Guthrie, 2020). Kayikci

et al. (2022) admitted that BT resolving major challenges, such as

traceability, trust, and accountability in the food industry.

The

second group is focus on circular economy. Though BT adoption to boost circular

economy has been mostly at the demonstration and piloting stage (Kouhizadeh et al., 2020; Wang et al., 2019), Nandi et al.

(2021) show significant patterns on adoption levels of the BT-enabled circular

economy system (BCES) and localization, agility and digitization (L-A-D) capability

development. For these authors, the greater the BCES adoption capabilities, the

greater the L-A-D capabilities.

For

example, even Blockchain promotes cooperation between the main players in the

aviation industry and the air traffic controllers to reduce fragmentation,

inefficiency, and uncoordinated operations, or allows information and data

sharing, Di Vaio and Varriale

(2020) show that Blockchain it is still not possible to observe a high level of

sustainable performance.

Authors

use different methods to address the impact of digitalization on SC as

presented in the section below.

3.3 Methods

developed in papers on digitilization

These

researches are developed within several sectors. The most representative is

manufacturing industry (fashion, agribusiness, automotive, energy, …), service

industry (transport, logistic, tourism retailing, …), Healthcare…

Quantitative

methods are the most representative in research on digitalization over the

period studied (36,36%) followed by Qualitative methods (35,40%). Conceptual

researches represent about 24%. This result may explain the maturation path

followed by research on digitalization. The table below provides details of

methods used by authors in this review.

Table 4 : Methods developed

|

Methods

|

Method details

|

Number

|

|

Conceptual

|

Review/conceptual

framework

|

50

|

|

Qualitative methods

|

Case study

|

34

|

|

Delphi

|

8

|

|

Semi structured interview

|

32

|

|

Quantitative methods

|

SEM Methods

|

23

|

|

Mathematical/simulation

|

29

|

|

Others

(Multivariate analysis, regression, …)

|

24

|

|

Mixed methods

|

Interview-survey

|

9

|

|

Total

|

209

|

Even

if the importance of technology is highlighted in the SC, the remain many

reasons that prevent managers to adopt it. Section 3.4 presents some of them.

3.4 Barriers to the

implementation of digitalization

There

are numerous barriers on the adoption of digitalization and Industry 4.0. This

can overall be attributed to the stigmas left by previous technologies (ERP for

example), ignorance or fear of the unknown among some managers and their

perceived adoption costs (Papathanasiou et al.,

2020).

Lack

of transparency in information is one of most important barrier. As pointed out

Derrouiche (2022), information integrity, transparency, and security are

necessary requirements for Supply Chain 4.0 applications, especially when there

are several stakeholders sharing and processing sensitive data. Lesueur-Cazé et al. (2022) pointed out the governance

issues as the mayor difficulty in Blockchain adoption within SC.

For

some authors, the non-adoption of Industry 4.0 isofar

attributed to the reluctance of some stakeholders, or due to the lack of

standard architecture, to Internet access difficulties, contractual problems,

confidentiality and security issues and the underdevelopment issue (Chauhan et

al., 2021; Kamble et al., 2019). For example, in the

electronic marketplace, Benzidia (2014) found that,

the mayor challenge remains the security and technological reliability issue

for succeed in reverse auction. But there is also the matter of organizational

culture, process re-engineering and staff resistance to change that can hinder

the implementation of technology (Derrouiche, 2022). More, it can be the matter

of organizational inertia, financial constraints or lack of resources sharing

within the food supply chain (Ali et al., 2021).

For

others, factors such as : "no sense of urgency", lack of industry

specific guidelines, lack of digital skills and talents (Nguyen et al., 2015),

lack of an overall digitalization strategy and competing priorities (Kane et

al., 2015), lack of understanding and lack of top management commitment; lack

of support and absence of government policies; and poor level of research and

development, high implementation and running costs; fear of failure;

compatibility issues are the main obstacles to the adoption of Industry 4.0

(Agrawal et al., 2019; Majumdar et al., 2020). In the SMEs sector, Stentoft et al. (2020) found that it is the lack of

managers perception of Industry 4.0, and not their perception of the high

barriers of Industry 4.0, that hinders the SME development readiness for

technology. Finally, for Haddud et al. (2017), IoT

challenges are still perceived as major obstacles to their adoption.

From

the above developments, many implications can be drawn. Section 4 highlights some.

4. IMPLICATIONS

According

to Papathanasiou et al. (2020), ERP transformations

have left organisations fatigued and disinclined towards further systems

development and resistant to subsequent change. Yet they are well aware of the

positive contributions of technologies such as blockchain on business

practices. This therefore implies for managers to first and foremost carry out

a check-up of the company's current technology state before embarking on a new

one that would overlap the existing without, however, providing any real

perceived value.

For

Chauhan et al. (2021), intrinsic barriers (vs extrinsic) are more important and

relevant for the adoption of Industry 4.0. This assume that if we fail in

specifying the objectives of digitalization and in the clarifying process of its

potential benefits and costs, it will be difficult to remove reluctances and

take advantage of its prowess. Like these authors, and with the accordance of

the resource-based view theory, we urge managers to take into account the

availability of both material and human resources. They will better do this by

preparing the different stakeholders both through training and communication.

In

addition, industries in developing economies are still struggling to embrace

Industry 4.0. The actors are specifically interested in technologies that allow

them to strengthen their productivity in order to ensure their economies of

scale and therefore reduce costs to offer a price matching the customers

income. While, the implementation of technologies such as blockchain or IoT

would stimulate trust between partners and speed up the innovation process,

which are another source of competitiveness.

Although

represented in the papers analyzed, the

implementation of Industry 4.0 in retail chains does not interest researchers

as much as the upstream part of the chain or the firm internal process

management. Yet Piroth et al. (2020) find that

logistics issues and technological infrastructure are viewed as key drivers of

online grocery retailing. Retail chains should therefore take greater ownership

of these technologies to improve their services.

5. CONCLUSION

This

research aimed to analyze the papers dealing with the

impacts of digitalization and mainly of Industry 4.0, Blockchain and IoT on the

supply chain. It emerges that it is a new subject which is arousing more and

more the researchers’ interest in observing the ever-increasing number of

publications. The impacts observed are numerous and cover a wide spectrum of

themes specific to various types of industries and environments. Some barriers

are presented, but also some implications aimed at drawing attention both to vigilance

in choice of technology, but also to the unavoidable nature of this new

industrial revolution for the supply chain.

The

attempt to splitting the themes or technologies analyzed,

which is certainly interesting for understanding the research directions,

remains poorly realistic. For example, it is difficult to be able to clearly

distinguish between articles dealing with digitalization from those dealing with Industry 4.0. Future researches

must consider this. The choice made on the HCERES journals repository restricts

the scope of the literature review analysis initiated. We plan to expand this

field in our future research.

6. REFERENCES

Agrawal, P., Narain, R., &

Ullah, I. (2019). Analysis of barriers in implementation of digital

transformation of supply c²hain using interpretive structural modelling

approach. Journal of Modelling in

Management https://doi.org/10.1108/JM2-03-2019-0066

Ali, I., & Thai, V. V.

(2020). Adopting Industry 4. 0 Technologies in Agri-Food Supply Chains: An

Exploratory Investigation of Drivers and Barriers.

Azzi, R., Chamoun, R. K.,

& Sokhn, M. (2019). The power of a blockchain-based supply chain. Computers

& industrial engineering, 135, 582-592. https://doi.org/10.1016/j.cie.2019.06.042

Ben-Daya, M., Hassini, E.,

& Bahroun, Z. (2019). Internet of things and supply chain management : a

literature review. International Journal of Production Research,

57(15-16),4719-4742. https://doi.org/10.1080/00207543.2017.1402140

Benhayoun, L., &

Saikouk, T. (2022). Distinction des facteurs critiques de succès pour

l’adoption de la blockchain en supply, Revue Française de gestion Industrielle,

2022, Vol. 36, No. 1, 27-59. https://doi.org/10.53102/2022.36.01.915

Benzidia, S. (2012). Les places de marché

électroniques: vers une e-supply chain coopérative. Revue française de gestion

industrielle, 31(1),59-82. https://doi.org/10.53102/2012.31.01.647

Benzidia, S. (2014). Les apports transactionnels

et relationnels des enchères inversées B2B. Revue française de gestion

industrielle, 33(1), 105-121. https://doi.org/10.53102/2014.33.01.720

Blanchet, M. 2016. Industrie 4.0. Nouvelle donne

industrielle, nouveau modèle économique. Lignes de Repères (éd.). Imprimé en

UE. https://doi.org/10.3917/oute1.046.0062

Bloomberg, J. (2018).

Digitization, digitalization, and digital transformation: confuse them at your

peril. Forbes. Retrieved on August, 28, 2019.

Chauhan, C., Singh, A.,

&Luthra, S. (2021). Barriers to industry 4.0 adoption and its performance

implications : An empirical investigation of emerging economy. Journal of

Cleaner Production, 285, 124809. https://doi.org/10.1016/j.jclepro.2020.124809

Cole, R., Stevenson, M.,

& Aitken, J. (2019). Blockchain technology: implications for operations and

supply chain management. Supply Chain Management: An International Journal,

24(4), 469-483. https://doi.org/10.1108/SCM-09-2018-0309

Colicchia, C., and F.

Strozzi. 2012. “Supply Chain Risk Management: A New Methodology for a

Systematic Literature Review.” Supply Chain Management: An International Journal

17 (4): 403–418. https://doi.org/10.1108/13598541211246558

Couzineau-Zegwaard, E. (2020). L’impact de la

digitalisation sur l’écosystème d’affaires de la Supply chain. La Revue des

Sciences de Gestion, (1), 85-97. https://doi.org/10.3917/rsg.300.0086

Cui, L., Gao, M., Dai, J.,

& Mou, J. (2022). Improving supply chain collaboration through operational

excellence approaches: an IoT perspective. Industrial Management & Data

Systems, 122(3), 565-591. https://doi.org/10.1108/IMDS-01-2020-0016

Daxböck, C., Kröber, J. and

Bergmann, M. (2019), “Digitized performance management along the supply chain”,

Performance Management in Retail and the Consumer GoodsIndustry, Springer,

Cham, pp. 405-423. https://doi.org/10.1007/978-3-030-12730-5_26

de Oliveira, U. R.,

Espindola, L. S., da Silva, I. R., da Silva, I. N., & Rocha, H. M. (2018).

A systematic literature review on green supply chain management: Research

implications and future perspectives. Journal of cleaner production, 187,

537-561. https://doi.org/10.1016/j.jclepro.2018.03.083

De Vass, T., Shee, H., &

Miah, S. J. (2021). Iot in supply chain management: a narrative on retail

sector sustainability. International Journal of Logistics Research and

Applications, 24(6), 605-624. https://doi.org/10.1080/13675567.2020.1787970

Derrouiche, R. (2022).

Supply Chain 4.0: Improving supply chains with analytics and Industry 4.0

technologies, Emel Aktas, Michael Bourlakis, Ioannis Minis, Vasileios

Zeimpekis. Revue Française de Gestion Industrielle, 36(1), 124-129. https://doi.org/10.53102/2022.36.01.1111

Di Vaio, A., & Varriale, L. (2020). Blockchain technology in supply chain management for sustainable

performance: Evidence from the airport industry. International Journal of

Information Management, 52, 102014. https://doi.org/10.1016/j.ijinfomgt.2019.09.010

Dubey, R., Gunasekaran, A.,

Bryde, D. J., Dwivedi, Y. K., & Papadopoulos, T. (2020). Blockchain

technology for enhancing swift-trust, collaboration and resilience within a

humanitarian supply chain setting. International journal of Production

research, 58(11), 3381-3398. https://doi.org/10.1080/00207543.2020.1722860

Ellis, S., Morris, H. D.,

& Santagate, J. (2015). IoT-enabled analytic applications revolutionize

supply chain planning and execution. International Data Corporation (IDC) White

Paper, 13, 259697.

Fel, F., Cayla, J., &

Carbone, V. (2020). L’industrie 4.0 peut-elle favoriser une

relocalisation de la production en France?. Logistique

& Management, 28(1), 18-28. https://doi.org/10.1080/12507970.2019.1683477

Forrester Research (2008),

The Growth of Social Technology Adoption, Forrester Research, Cambridge, MA.

Fosso Wamba, S., &

Guthrie, C. (2020). The impact of blockchain adoption on competitive

performance: the mediating role of process and relational innovation. Logistique

& Management, 28(1), 88-96. https://doi.org/10.1080/12507970.2019.1679046

Gupta, H., Kumar, S., Kusi-Sarpong, S., Jabbour,

C. J. C., &Agyemang, M. (2020). Enablers to supply

chain performance on the basis of digitization technologies. Industrial

Management & Data Systems. https://doi.org/10.1108/IMDS-07-2020-0421

Haddud, A., DeSouza, A.,

Khare, A., & Lee, H. (2017). Examining potential benefits and challenges

associated with the Internet of Things integration in supply chains. Journal of

Manufacturing Technology Management. https://doi.org/10.1108/JMTM-05-2017-0094

Heavin, C., & Power, D.

J. (2018). Challenges for digital transformation–towards a conceptual decision

support guide for managers. Journal of Decision Systems, 27, 38–45. https://doi.org/10.1080/12460125.2018.1468697

Hennelly, P.A., Srai, J.S.,

Graham, G. and Fosso Wamba, S. (2020), “Rethinking supply chains in the age of

digitalization”, Production Planning and Control, Vol.31 Nos 2-3, pp. 93-95. https://doi.org/10.1080/09537287.2019.1631469

Hess, T., Benlian, A., Matt,

C., & Wiesb¨ock, F. (2016). Options for formulating a digital

transformation strategy. MIS Quarterly Executive, 15(2), 123–139.

Irannezhad, E. (2020). Is

blockchain a solution for logistics and freight transportation problems?

Transportation Research Procedia, 48,

290-306. https://doi.org/10.1016/j.trpro.20

20.08.023

Jabbour, C.J.C., Fiorini,

P.D.C., Ndubisi, N.O., de Queiroz, M.M. and Piato, E.L. (2020),

“Digitally-enabled sustainable supply chains in the 21st century : a review and

a research agenda”, The Science of the Total Environment, 138177. https://doi.org/10.1016/j.scitotenv.2020.138177

Kagermann, H., Wahlster, W.,

and Helbig, J., (2013), Recommendations for implementing the strategic

initiative Industrie 4.0 – Final report of the Industrie 4.0 Working Group.

Frankfurt am Main : Communication Promoters Group of the Industry-Science

Research Alliance, acatech.

Kamble, S., Gunasekaran, A.,

&Arha, H. (2019). Understanding the Blockchain technology adoption in

supply chains-Indian context. International Journal of Production Research,

57(7), 2009-2033. https://doi.org/10.

1080/00207543.2018.1518610

Kane, G. C., Palmer, D.,

Phillips, A. N., Kiron, D., & Buckley, N. (2015). Strategy, not technology,

drives digital transformation. MIT Sloan Management Review.

Kayikci, Y., Subramanian, N., Dora, M., &

Bhatia, M. S. (2022). Food supply chain in the era

of Industry 4.0: Blockchain technology implementation opportunities and

impediments from the perspective of people, process, performance, and

technology. Production planning & control, 33(2-3), 301-321. https://doi.org/10.1080/09537287.2020.1810757

Kergroach, S. (2021). SMEs

Going Digital: Policy challenges and recommendations. Going Digital Toolkit

Note,15. https://doi.org/10.1787/c91088a4-en

Khin, S., & Ho, T. C.

(2019). Digital technology, digital capability and organizational performance.

International Journal of Innovation Science, 11(2), 177–195. https://doi.org/10.1108/ijis-08-2018-0083

Kirtley, J., & O’Mahony,

S. (2020). What is a pivot? Explaining when and how entrepreneurial firms

decide to make strategic change and pivot. Strategic Management Journal. https://doi.org/10.1002/smj.3131

Kouhizadeh, M., Zhu, Q.,

& Sarkis, J. (2020). Blockchain and the circular economy: potential

tensions and critical reflections from practice. Production Planning &

Control, 31(11-12), 950-966. https://doi.org/10.1080/09537287.2019.1695925

Kraus, S., Durst, S.,

Ferreira, J. J., Veiga, P., Kailer, N., & Weinmann, A. (2022). Digital

transformation in business and management research: An overview of the current

status quo. International Journal of Information Management, 63, 102466. https://doi.org/10.1016/j.ijinfomgt.2021.102466

Lasi, H., Fettke, P.,

Kemper, H. G., Feld, T., & Hoffmann, M. (2014). Industry 4.0. Business

& Information Systems Engineering, 6(4), 239. https://doi.org/10.1007/s12599-014-0334-4

Lee H.L. etBillington C,

(1993), Material management in decentralized supply chain", Operations

Research, vol 41, n°5, p. 835-847. https://doi.org/10.1287/opre.41.5.835

Legenvre, H., Henke, M.,

& Ruile, H. (2020). Making sense of the impact of the internet of things on

Purchasing and Supply Management: A tension perspective. Journal of Purchasing

and Supply Management, 26(1), 100596. https://doi.org/10.1016/j.pursup.2019.100596

Lesueur-Cazé, M., Bironneau, L., Lux, G., &

Morvan, T. (2022). Réflexions sur les usages de la blockchain pour la

logistique et le Supply Chain Management: une approche prospective. Revue

française de gestion industrielle, 36(1), 60-82. https://doi.org/10.53102/2022.36.01.917

Li, F. (2020bbb). The

digital transformation of business models in the creative industries: A

holistic framework and emerging trends. Technovation, 92–93, Article

102012. https://doi.org/10.1016/j.technovation.2017.12.004

Majumdar, A., Garg, H., & Jain, R. (2020). Managing the barriers of Industry 4.0 adoption and implementation in

textile and clothing industry: Interpretive structural model and triple helix

framework. Computers in Industry, 103372. https://doi.org/10.1016/j.compind.

2020.103372

Martinez, V., Zhao, M.,

Blujdea, C., Han, X., Neely, A., & Albores, P. (2019). Blockchain-driven

customer order management. International Journal of Operations & Production

Management, 39(6/7/8), 993-1022. https://doi.org/10.1108/IJOPM-01-2019-0100

Müller, J. M., Buliga, O., & Voigt, K.-I.

(2021). The role of absorptive capacity and innovation

strategy in the design of industry 4.0 business models - A comparison between

SMEs and large enterprises. European Management Journal, 39(3), 333–343. https://doi.org/10.1016/j.emj.2020.01.002

Nandi, M. L., Nandi, S.,

Moya, H., & Kaynak, H. (2020). Blockchain technology-enabled supply chain

systems and supply chain performance: a resource-based view. Supply Chain

Management: An International Journal, 25(6), 841-862. https://doi.org/10.1108/SCM-12-2019-0444

Nandi, S., Sarkis, J.,

Hervani, A., & Helms, M. (2021). Do blockchain and circular economy

practices improve post COVID-19 supply chains? A resource-based and resource

dependence perspective. Industrial Management & Data Systems, 121(2),

333-363. https://doi.org/10.1108/IMDS-09-2020-0560

Nguyen, T. H., Newby, M.,

& Macaulay, M. J. (2015). Information technology adoption in small

business: Confirmation of a proposed framework. Journal of Small Business

Management, 53(1), 207–227. https://doi.org/10.1111/jsbm.12058

Papathanasiou, A., Cole, R.,

& Murray, P. (2020). The (non-) application of blockchain technology in the

Greek shipping industry. European Management Journal, 38(6), 927-938. https://doi.org/10.1016/j.emj.2 020.04.007

Parviainen, P., Tihinen, M.,

Kääriäinen, J., & Teppola, S. (2017). Tackling the digitalization

challenge: how to benefit from digitalization in practice. International

journal of information systems and project management, 5(1), 63-77. https://doi.org/10.12821/ijispm050104

Piroth, P., Rüger-Muck, E.,

& Bruwer, J. (2020). Digitalisation in grocery retailing in Germany: an

exploratory study. The International Review of Retail, Distribution and

Consumer Research, 30(5), 479-497. https://doi.org/10.1080/09593969.2020.1738260

PRIM, A. L., NICCHELLATTI, T. P., & MENDES, R.

G. (2021). Improving cold-food quality control through the

Internet of Things and big data. Supply Chain 4.0: Improving Supply Chains with

Analytics and Industry 4.0 Technologies, 171.

Queiroz, M. M., Fosso Wamba, S., De Bourmont, M.,

& Telles, R. (2021). Blockchain adoption in

operations and supply chain management: empirical evidence from an emerging

economy. International Journal of Production Research, 59(20), 6087-6103. https://doi.org/10.1080/00207543.2020.1803511

Queiroz, M. M., Telles, R.,

& Bonilla, S. H. (2020). Blockchain and supply chain management

integration: a systematic review of the literature. Supply chain management: An

international journal, 25(2), 241-254. https://doi.org/10.1108/SCM-03-2018-0143

Reinhardt, I. C., Oliveira,

J. C., & Ring, D. T. (2020). Current perspectives on the development of

Industry 4.0 in the pharmaceutical sector. Journal of Industrial Information

Integration, 18, 100131. https://doi.org/10.1016/j.jii.2020.10013

Rogerson, M., & Parry,

G. C. (2020). Blockchain: case studies in food supply chain visibility. Supply

Chain Management: An International Journal, 25(5), 601-614. https://doi.org/10.1108/SCM-08-2019-0300

Saberi, S., Kouhizadeh, M.,

Sarkis, J., & Shen, L. (2019). Blockchain techn²ology and its relationships

to sustainable supply chain management. International Journal of Production

Research, 57(7), 2117–2135. https://doi.org/10.1080/00207543.2018.1533261

Skare, M., de Obesso, M. D.

L. M., & Ribeiro-Navarrete, S. (2023). Digital transformation and European

small and medium enterprises (SMEs): A comparative study using digital economy

and society index data. International Journal of Information Management, 68,

102594. https://doi.org/10.1016/j.ijinfomgt.2022.102594

Stentoft, J., Adsbøll Wickstrøm,

K., Philipsen, K., & Haug, A. (2020). Drivers and barriers for Industry 4.0

readiness and practice :empirical evidence from small and medium-sized

manufacturers. Production Planning & Control, 1-18. https://doi.org/10.1080/09537287.2020.1768318

Swan, M., 2015. Blockchain

:Blueprint for a New Economy, " O'Reilly Media, Inc.".ISBN:

1491920475.

Swanson, D. (2017, January).

The impact of digitization on product offerings: using direct digital

manufacturing in the supplychain. In Proceedings of the 50th Hawaii

International Conference on System Sciences. https://doi.org/10.24251/HICSS.2017.508

Taiminen, H. M.,

&Karjaluoto, H. (2015). The usage of digital marketing channels in SMEs.

Journal of Small Business and Enterprise Development. https://doi.org/10.11

08/JS BED-05-2013-0073

Tian, F. (2016). An

agri-food supply chain traceability system for China based on RFID &

blockchain technology. 2016 13th International Conference on Service Systems

and Service Management, ICSSSM 2016, 1–6. https://doi.org/10.1109/ICSSSM.2016.7538424

Tu, M. (2018), “An

exploratory study of Internet of Things (IoT) adoption intention in logistics

and supply chain management”, International Journal of Logistics Management,

Vol. 29 No. 1, pp. 131-151. https://doi.org/10.1108/IJLM-11-2016-0274

Tu, M., K. Lim, M., & Yang, M. F. (2018). IoT-based production logistics and supply chain system–Part 2: IoT-based

cyber-physical system: a framework and evaluation. Industrial Management &

Data Systems, 118(1), 96-125. https://doi.org/10.1108/IMDS-11-2016-0503

Vétois, P., & Raimbault,

N. (2017). L’« uberisation» de la logistique: disruption ou

continuité? Le cas de l’Île-de-France. Technologie et innovation, 17(3), 22.

Wamba, S. F., & Queiroz, M. M. (2022). Industry 4.0 and the supply chain digitalisation: a blockchain diffusion

perspective. Production Planning & Control, 33(2-3), 193-210. https://doi.org/10.1080/09537287.2020.1810756

Wang, Y., Han, J. H., &

Beynon-Davies, P. (2019). Understanding blockchain technology for future supply

chains: a systematic literature review and research agenda. Supply Chain

Management: An International Journal, 24(1), 62-84. https://doi.org/10.1108/SCM-03-2018-0148

Wang, Y., Singgih, M., Wang,

J., & Rit, M. (2019). Making sense of blockchain technology: How will it

transform supply chains?. International Journal of Production Economics, 211,

221-236. https://doi.org/10.1016/j.ijpe.2019.02.002

Wong, L. W., Tan, G. W. H.,

Lee, V. H., Ooi, K. B., & Sohal, A. (2020). Unearthing the determinants of

Blockchain adoption in supply chain management. International Journal of

Production Research, 58(7), 2100-2123. https://doi.org/10.1080/00207543.2020.1730463

Wu, L., Yue, X., Jin, A.,

& Yen, D. C. (2016). Smart supply chain management : a review and

implications for future research. The International Journal of Logistics

Management, 27(2), 395-417. https://doi.org/10.1108/IJLM-02-2014-0035

7.

BIOGRAPHIE

Célestin ELOCK SON is a

researcher at CEREFIGE. He is a senior lecturer in Management Sciences at the

University of Lorraine at the Transport and Logistics Management department of

IUT de Moselle-Est. Holder of a PhD from the Université d'Artois, his research

focuses on retail logistics. In particular, it analyzes retailers and consumers

behaviors, study the risks associated with the distribution of food product. He

is also interested in new distribution methods brought about by the

digitization of the supply chain.

Célestin ELOCK SON is a

researcher at CEREFIGE. He is a senior lecturer in Management Sciences at the

University of Lorraine at the Transport and Logistics Management department of

IUT de Moselle-Est. Holder of a PhD from the Université d'Artois, his research

focuses on retail logistics. In particular, it analyzes retailers and consumers

behaviors, study the risks associated with the distribution of food product. He

is also interested in new distribution methods brought about by the

digitization of the supply chain.

Jean

Noel BREKA is a

researcher at CEREFIGE. He is a senior lecturer in Management Sciences at the

University of Lorraine at the Transport and Logistics Management department of

IUT de Moselle-Est. He holds a PhD from the University of Paris 1 - Panthéon

Sorbonne. He specializes in Operations Management and Supply Chain. His

research focuses on industry 4.0, green logistics, CSR, functional economy and

circular economy

Jean

Noel BREKA is a

researcher at CEREFIGE. He is a senior lecturer in Management Sciences at the

University of Lorraine at the Transport and Logistics Management department of

IUT de Moselle-Est. He holds a PhD from the University of Paris 1 - Panthéon

Sorbonne. He specializes in Operations Management and Supply Chain. His

research focuses on industry 4.0, green logistics, CSR, functional economy and

circular economy

1, Jean Noel Breka2